Eastman Chemical Company (NYSE:EMN) Q4 2023 Earnings Call Transcript February 2, 2024

Eastman Chemical Company isn’t one of the 30 most popular stocks among hedge funds at the end of the third quarter (see the details here).

Operator: Good day everyone and welcome to the Fourth Quarter Full Year 2023 Eastman Conference Call. Today’s conference is being recorded. This call is being broadcast live on the Eastman website, www.eastman.com. We will now turn the call over to Mr. Greg Riddle of Eastman Investor Relations. Please go ahead.

Greg Riddle: Thank you, Alex and good morning, everyone and thanks for joining us. On the call with me today are Mark Costa, Board Chair and CEO; Willie McLain, Executive Vice President and CFO; and Jake LaRoe, Manager, Investor Relations. Yesterday after market closed, we posted our fourth quarter and full year 2023 financial results news release and SEC 8-K filing, our slides and the related prepared remarks in the Investor Relations section of our website, www.eastman.com. Before we begin, I’ll cover 2 items. First, during this presentation, you will hear forward-looking statements concerning our plans and expectations. Actual events or results could differ materially. Certain factors related to future expectations are or will be detailed in our fourth quarter and full year 2023 financial results news release during this call, in the preceding slides and prepared remarks and in our filings with the Securities and Exchange Commission, including the Form 10-K filed for full year 2022 and the Form 10-K to be filed for full year 2023.

Second, earnings referenced in this presentation exclude certain noncore and unusual items. Reconciliations to the most directly comparable GAAP financial measures and other associated disclosures including the description of the excluded and adjusted items are available in the fourth quarter and full year 2023 financial results news release. I’d like to now turn the call over to Mark for some remarks.

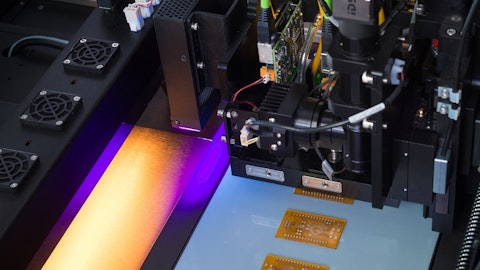

Mark Costa: Before I jump into the Q&A, I do want to take the opportunity to recognize the team that’s been working on the methanolysis plant. There’s a huge team out there that’s been working tremendously since our last call in October to commission and start up this facility and get us to the point where we’re introducing feedstock. And that’s a real remarkable accomplishment when you look over this time frame. They’ve worked incredibly hard through the holidays. They’ve made a lot of personal sacrifice and they’ve got us to this stage. And it’s a real testament to their dedication and belief in the company and the excitement that every owner of this company has around building the circular economy. And it’s also a real great example of the power of our Tennessee site.

Its scale and integration has really enabled this start-up process to go this quickly and well. Because we have such a huge vast set of resources and capabilities, it literally allowed us to swing a lot of those people from different parts of the plant into this start-up process and make a significant difference. So I just wanted to express my thanks to all of the people who’ve been involved in this process. It’s been a tremendous program and one that they really did make a lot of sacrifice and we deeply appreciate it. With that, we’ll open it up to Q&A.

See also 20 Highest Quality Beers in the US and 12 Best American Bank Stocks To Buy According to Analysts.

Q&A Session

Follow Eastman Chemical Co (NYSE:EMN)

Follow Eastman Chemical Co (NYSE:EMN)

Receive real-time insider trading and news alerts

Operator: [Operator Instructions] Our first question for today comes from Josh Spector of UBS.

Josh Spector: I actually wanted to follow up on the methanol facility first — the methanolysis facility. So you’re near getting on-spec product out. But I was wondering if you could talk through kind of the milestones as you go through this year. So when do you get to the point where you say yields are as expected? Do you think you can get to the full operational capacity and the cost structure and therefore, the EBITDA becomes in line with your long-term expectations?

Mark Costa: It’s a question one we’re very focused on. And we are very excited to be at the stage we’re at right now. As we said in our comments, we’re at the point where we’ve been starting up the facility, completed all the commissioning, introducing feedstock and that will start to be processed. And the front end of the plant takes a little bit of time to do that, to get the system properly charged and then it starts going through the plant. So we feel that we’re in good shape to be on spec here soon with material recognizing revenue and getting that process going and serving our customers who are very eager to get product from us. And when I say soon, I mean sort of days or weeks in where we sit right now. So we feel like we’re on track with starting up the plant and serving customer demand relative to that $75 million.

Now as you talk about the plant side of this, you don’t go from the plants producing on-spec material the full ramp-up rates overnight. It takes a few months to line out the facility, optimize its operations and make sure that everything is working properly as you scale it up. And so we’ll be doing that and ramping up the production. But the way this plant works and the way we can get the recycled content out, we should be able to start getting revenue relatively soon. When it comes to the demand side of things — and by the way, cost structure will line out over time. Right now, we’re still in that pre-production phase. Expenses are a bit higher than when you just are pulling the operating resources back to sort of steady state. So front end of this from a cost point of view is a little loaded as you would expect.

The demand side, I’d say, is actually quite good. So what’s different than most plants in this situation is we didn’t start selling recycled content when the plant starts, we started it over a year ago. We have a technology called glycolysis; it’s a bridging technology where we can use our existing assets. You can use sort of clean, clear bottles which is what you have to have with glycolysis to then make recycled content. So long term, it’s not a great strategy because it’s very high cost to buy those clean bottles and it’s not a very efficient process in using your existing assets. But what it did allow us to do is supply recycled content polymer to a number of brands. In fact, the brands that you can see on that slide in the presentation we provided have already been selling our recycled content from that technology into the marketplace.

So we’re not trying to ramp them up. They’re already ready to go in the market and very anxious to get material from us to sort of accelerate volume build into this year. So that really helps us both know that we can get the price premiums we want to support our economics as well as we have a number of customers that are going to sort of buy the moment we have product coming out of the plant. And then there are a bunch of other brands we’ve been working on that we just didn’t have the capacity to serve last year that are also very interested in the product and so we’ll be qualifying them and ramping them up. So what you have is a situation where the ramp-up will start to help Q2 relative to Q1 but really sort of make a big difference in the second half relative to the first half of where you see this incremental EBITDA.

The last point I would mention is on the cost side, normally, when you build a big specialty plant, you have a huge headwind in operating costs as you start up. And we certainly have operating costs for this plant. But they are really sort of offset by the pre-production expense of last year and the higher cost of this glycolysis process I just mentioned. So the costs are relatively neutral. And so that helps the revenue be — flow pretty fast to EBITDA through that sort of year-over-year sort of steady cost structure, if you will. So that’s the sort of key components of it. We’re very focused on just keeping the process going right now. And as I said earlier, it’s just a tremendous example of teamwork out there who are doing this through winter weather and freezing conditions, et cetera, to get this plant running.

Josh Spector: And maybe just quickly, so as you go through all that, you made some comments that you wouldn’t FID the next plant until this plant is done. I guess, is that just on-spec product? Or is there at some point, production yield or some other metric you’re looking at to say we’re good; the design is fine, there’s — like we’re going to move ahead with that project? Because you seem pretty bullish about getting the customer commitments that second plant soon, so I’m just wondering what’s the limiting factor there.

Mark Costa: Yes. There are a couple of limiting factors. One, obviously, is we want to see the Kingsport plant technology up and running. And as you said, we want to see that the yields and efficiency are what we expect them to be, the plants running operationally well. And as I said, that’s in the next couple of months that we’ll sort of get those insights and knowledge to feel comfortable about the quality of this plant. Because it’s important to keep in mind that to minimize capital risk and construction risk, we’re going to leverage and build the same plant, right, in France in the second plant. And there’s obviously improvements we’ll learn through this process. But same scale, same design, so that — really leveraging all the learning that we’ve gone through in this plant to do a better job in how we build the second and third plants.

So that, I think, is in the time frame of what we’re talking about right now from an FID point of view. The customer contracts are obviously the second component of that — of making that decision and the incentives for the project getting finalized is the third part. We feel good about all those. And we think, again, in the same kind of time frame, in the next several months, we should be in a position to have FID. When construction starts is a little bit different than declaring FID. We’re still completing the engineering, we have permitting to do on the environmental side and building permitting that is ongoing as we speak. So we’re not talking about starting actual construction until — soon as probably late summer with the path that we’re on right now.

And that gives us all of that time to make sure we believe in how the plant is operating before you start turning dirt on the second and third plants.

Operator: Our next question comes from David Begleiter from Deutsche Bank.

David Begleiter: Mark, some of your customers and peers this earnings season have noted some modest stabilization, improvement in certain markets, underlying demand. Are you seeing any of that in any of your geographies or key markets?

Mark Costa: Certainly, David. What I’d say is we are seeing stable — I mean stabilization, absolutely. So our guidance is built on thinking that primary demand this year is going to be similar to last year in the sort of discretionary markets. And in the stable markets like personal care, water treatment, consumer packaging, et cetera, we would expect sort of modest growth from last year. Now to be clear, last year’s demand — primary demand was low. We’re not predicting an improvement in any meaningful way from those sort of low levels we were at from — through last year. What I would say is — and automotive, we actually are — was growing last year and we think it’s going to be more flattish this year. So that’s sort of where we are in the primary demand as we sort of showed on the slide that we supplied to you guys.

The key driver for pretty significant volume increase for us this year versus last year is really the sort of lack of destocking when you think about the sort of volume mix impact of last year, driving earnings down about $450 million. And what we said in October, I think it’s still true. You assume about 1/3 of that is destocking, it’s probably a bit more than that but to play it safe, we’ll call it 1/3. That’s $150 million of a lack of a demand headwind from last year relative to this year. It’s like an easy comp. And we can see the evidence of that playing out already in the fourth quarter in some markets and certainly into the first. So for example, the durables business which — consumer durables business which is the one that was most impacted from a demand drop last year.