3D Systems Corporation (NYSE:DDD) Q3 2023 Earnings Call Transcript November 8, 2023

3D Systems Corporation beats earnings expectations. Reported EPS is $0.01, expectations were $-0.06.

Operator: Hello and welcome to the 3D Systems’ Q3 2023 Conference Call and Webcast. [Operator Instructions] A question-and-answer session will follow the formal presentation. [Operator Instructions] As a reminder, this conference is being recorded. It’s now my pleasure to turn the call over to Mick McCloskey, Vice President, Investor Relations. Please go ahead, Mick.

Mick McCloskey: Good morning and welcome to 3D Systems’ third quarter 2023 conference call. With me on today’s call are Dr. Jeffrey Graves, President and Chief Executive Officer; and Andrew Johnson, Executive Vice President and Interim Chief Financial Officer. The webcast portion of this call contains a slide presentation that we will refer to during the call. Those following along on the phone who wish to access the slide portion of this presentation may do so on the Investor Relations section of our website. The following discussion and responses to your questions reflect management’s views as of today only and will include forward-looking statements as described on this slide. Actual results may differ materially. Additional information about factors that could potentially impact our financial results is included in this morning’s press release and our recent filings with the SEC, including our most recent annual report on Form 10-K and quarterly reports on Form 10-Q.

During this call, we will discuss certain non-GAAP financial measures. In our press release and slides accompanying this webcast, you will find additional disclosures regarding these non-GAAP measures, including reconciliations with comparable GAAP measures. Finally, unless otherwise stated, all comparisons in this call will be against our results for the comparable period of 2022. With that, I’ll turn the call over to our CEO, Jeff Graves, for opening remarks.

Jeffrey Graves: Thanks, Mick, and good morning, everyone. We appreciate you joining us today. Before I begin, I’d like to first acknowledge the unimaginable and tragic events that have happened in Israel over the last several weeks. Our company and in fact our entire additive manufacturing industry has deep ties to Israel where engineering breakthroughs have been made that have benefited people worldwide over many years. To our Israeli colleagues and to all of those impacted by the atrocities that were committed and by the ongoing turmoil in the region, please know that you’re in our thoughts and prayers for a rapid return to peace and security for all. May God bless you in these troubled times. Today we take this call from Frankfurt, Germany, where we’re showcasing our current and future technologies at Formnext, which for those of you who may be unfamiliar, is the largest global additive manufacturing conference that brings together a community of minds that will actively shape the next generation of intelligent industrial production.

Later in the call, I’ll offer a few insights that we’re sharing this week as we preview our exciting new technologies that will enter production in 2024. But let me start this morning by providing an overview of our third quarter 2023 results and some insights into the operating climate we anticipate over the next few quarters. I’ll then cover our recently announced restructuring initiative, which we expect to result in improved profitability and cash performance, while preserving crucial investments for future growth. The net result of these cost actions and investments will be the delivery of tangible near-term benefits and shareholder value, while accelerating the adoption of additive manufacturing in industrial and healthcare markets in the years ahead.

Given our scale as one of the largest pure-play additive manufacturing companies in the world and the strength of our balance sheet, we’re well positioned to execute these initiatives even in the face of a challenging macroeconomic and geopolitical environment. Then before handing the call off to our Interim CFO, Andy Johnson, I’ll briefly cover the incredible outlook for our new products and technologies, a record number of which are targeted for release in 2024. I’ll start on slide six with some perspective on our third quarter results and where we see the industry today. As I commented in this morning’s release and from what we shared in our announcement a few weeks ago, I firmly believe that additive manufacturing is rapidly establishing itself as a highly attractive production technology that can deliver unique value across virtually all industrial and healthcare markets.

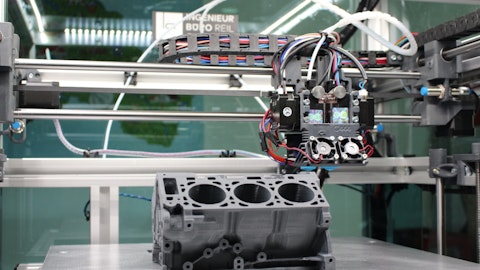

The ability to economically mass produce low volume, high mix components, or if desired, even fully customized products, is now being realized by companies worldwide. These production solutions bring unique value to our customers to improve component designs, reduce capital investment needs, and enhance sustainability. At 3D Systems we offer the broadest range of additive technologies in the industry, bringing together both metal and polymer hardware platforms, an exceptional materials portfolio, and intelligent cloud-based software with unmatched application focus to deliver bespoke solutions to our customers. To put it very simply, the maturing of 3D printing technology for production applications is the key long-term driver of exciting growth for our company and for the industry in total.

So with that said, why are we in the industry more broadly experiencing a weak overall demand environment for our products? Well, there are two very basic reasons. One is that inflation has increasingly impacted consumer discretionary spending, which in our case directly affects the sales into consumer products such as clear aligners for orthodontic treatment. The second, which is a much broader effect, is that the rising macroeconomic and geopolitical risks have caused our customers to slow capital spending on new production capacity, which affects their adoption of new production technologies, such as additive manufacturing. Rapid rise and higher for longer interest rate expectations combined with the macroeconomic risk factors have created a challenging financing environment that’s weighing on the speed and decisiveness of customers to invest capital to bring additive manufacturing more fully into the factory floor.

To be clear, there’s no decline in interest and direction, just the rate at which CapEx is being approved at executive levels. While our larger customers have strong balance sheets, they’re conserving cash until the future is clear. Smaller companies with weaker balance sheets are having to be even more careful. For 3D systems, this translated into weakening sales in Q3 and a more conservative outlook for future quarters. Without clear evidence of economic growth, we’re taking decisive actions to reduce our cost structure in order to ensure improved profitability and cash performance. These actions include headcount reductions, consolidation of our operating footprint, and other reductions in discretionary spending. Importantly, we are preserving our core investments in new technology and application development in order to ensure that we’re well positioned to deliver exciting growth when the macroeconomic turns more favorable.

To recap our third quarter performance, there was clearly pressure on revenue, but we were pleased with our operational execution and technology progress, both of which contributed to significant improvements in gross margin and profitability levels. Revenue for the quarter of roughly $124 million reflected softness in our dental sales, the overwhelming impact of which was clear aligners for orthodontics. It also reflected softness in printer sales driven by factors I mentioned previously. While we had anticipated the softness in dental, the printer sales sure fall was greater than anticipated, particularly late in the quarter as tensions in the world increased significantly. Moving forward, our dental business, based upon customer feedback, we anticipate the liner and market to stabilize, but with continued need to reduce inventory in the supply chain and weakness in consumer discretionary spending.

We would anticipate a slower recovery in 2024 than expected earlier in the year. Offsetting this to some extent is the continuing migration of orthodontic solutions from metal bracket and wires to clear aligners. With the progress being made in materials and printing technologies, we anticipate the gain of overall market share for these solutions to continue and to provide more growth opportunities in the future. But despite what we view as the significant to short-term headwinds, we’re making major strides to control what we can internally. Earlier this year, we implemented two waves of cost initiatives that are in line with our expectations and on track to deliver over $7 million of savings in 2023. In September, we announced incremental progress on the insourcing of metal and polymer production printers in our Riom, France and Rock Hill, South Carolina facilities.

These actions combined with a strong focus on supply chain optimization are enabling not only greater cost efficiencies, but enhanced quality control, reduced manufacturing cycle times, and the acceleration of new product introductions, all the while boosting customer satisfaction through shorter lead times, increased product support, and process customization. As we look to the future, we see the potential for improved asset management and resource utilization that are anticipated to reduce our total inventory significantly in 2024. With this mindset and internal focus, I’d point you to our strong gross margin performance and EBITDA performance delivered during the quarter. As it relates to these performance these metrics, we’re extremely encouraged by the progress we’ve made to date.

With the operational initiatives we undertook this year, much of which has only recently been completed, we’re even now starting to witness the benefits of what we’ve already implemented and where our newest wave of initiatives will continue to drive our future. With the new wave of initiatives we’ve kicked off, we’ll continue to drive to in-source operations into our key manufacturing locations and further optimize our supply chain, which we expect to favorably impact our cost of goods and operating efficiencies. These will continue to have a positive impact on gross margins, providing support even in a weaker external environment. I want to offer a sincere thanks to our operations team for their outstanding performance. They truly have delivered for us.

While our gross margins were greatly impacted by our operational execution, it’s important to note that both margin and EBITDA performance were also impacted by our technical progress, which were more extraordinary in nature and need to be called out separately. In this vein, one of the drivers behind our revenue margin and EBITDA performance relates to the outstanding progress made by our regenerative medicine team. As many of you know, we view regenerative medicine as perhaps the most exciting element of our long-term growth portfolio, and I believe that our work in this field is the most innovative in the entire industry. It has enormous potential to unlock significant value for our shareholders, helping to advance medicine and improve the lives of millions of people around the world.

We began this journey in 2017 when we partnered with United Therapeutics to embark on the task of printing the human lung, the most complex structure ever 3D printed, with a target for human trials by 2026. As I referenced in a public discussion in late June, we’ve been on track to achieve many clear-cut milestones with several critical inflection points in sight. Today, I’m pleased to share the amazing progress towards some of these milestones, which relate directly to the precision and accuracy of our bioprinters in combination with the extraordinary biomaterials needed to successfully print a human lung. This enabled us to recognize a benefit to our consolidated performance in the quarter. While irregular in timing, it provides tangible evidence of our progress in partnership with United Therapeutics, it continues to bolster our confidence in this new extraordinary market for the future.

Andy will take you through more of the specifics related to our margin and EBITDA performance for the quarter in a few moments, but let me end on a very clear note. We’re extremely encouraged by the progress we’ve made to date where we’ll continue to drive our future operating efficiencies and our path to sustain profitability. With this, we can weather the headwinds that we may face as we enter 2024 and emerge a stronger company, well positioned for exciting long-term growth. Now with that, let’s turn to slide seven for a deeper dive into our industrial solution segment. While the overall economic environment may have muted performance in industrial solutions, the business delivered growth from prior year. Our transportation and motor sports market drove the bulk of the growth during the quarter, as other stronger performing verticals, such as academic and research and service bureaus, commercial aviation and defense were offset by weakness in other markets more broadly.

I’d also like to call out a few announcements over the last few months that highlight why we’re so passionate about our future in the industrial markets. Our EXT Titan Pellet 3D Printer continues to build momentum. As mentioned on our prior call, we’ve seen strong momentum in the US market, and we’re now expanding into Canadian markets in earnest with our most recent announcement of Icon Technologies Limited Purchase of the first EXT 1270 in Canada. Icon provides innovative custom thermoform solutions to its OEM customers for applications such as recreational vehicles, building products and HVAC systems. Given the EXT Titan platform offers up to 88% raw material cost savings and up to 65% lead time production as compared to machine, metal, or cast ceramic alternatives.

It makes an exceptional match for efficiency-focused manufacturers like Icon that are interested in the direct production of thermoforming molds. In addition to North America and Europe, India and Japan are now opening as well with our EXT 1070 pellet printer receiving an exciting reception in recent weeks. Having the broadest range of technologies in the industry, I’d be remiss if I didn’t mention 2 of our more exciting metal printer announcements from the third quarter as well. In July, we were pleased to share our continued collaboration with Oerlikon AM. We purchased their fourth DMP Factory 500 system to further scale metal additive manufacturing for their customers. Combining both organizations’ deep process and applications expertise with our DMP Factory 500 and Oerlikon service engineering capabilities enables a faster path to market for applications in high-criticality industries, such as semiconductor and aerospace.

And in late September, we were awarded a $10. 8 million contract from the United States Air Force for a large-format metal 3D printer advanced technology demonstrator. The contract supports the development of large-scale, hypersonic-relevant additive manufacturing print capabilities, with work being performed in Rock Hill, South Carolina and San Diego, California and the expected contract completion date of September 29th, 2025. This work allows us to then commercialize the technology and support of the US Defense needs for the future, the key area targeted for growth in our future of our company. All are exciting examples of our exceptional ability to deliver metal and polymer solutions to a wide variety of industrial applications. In turning to health care solutions on slide eight.

As mentioned earlier this morning, within health care solutions, We contended with both consumer-related and broader economic factors that drove an 18% decline in revenues from prior year. This was predominantly driven by an expected decline in our dental business. Additionally, outside of dental, printer sales were also softer than anticipated. However, these effects were partially offset by our technical milestone progress in regenerative medicine business and another quarter of growth in personalized healthcare solutions. Keeping on that theme, I’d like to shed some incremental insight regarding our personalized health care solution business. Earlier this year, we shared with you the tufting story of the first 3D printed cranial implant used in surgery at the Salzburg University Hospital in Austria that was produced on our EXT 220 med extrusion printer platform with PEEK material.

PEEK is a medical grade high performance polymer material. And in spectacular fashion, once again, we recently shared another instance of the EXT 220 printer combined with PEEK, delivering a life-changing outcome. Leveraging our technology platform, a cranial implant was created by the team at the University Hospital in Basel. It was used to successfully replace a section of disintegrating skull in a 46-year-old male who was experiencing complications from a stroke in 2019. Both of these recent announcements are prime examples of the way that additive manufacturing is changing the future of health care. And as the cranial implant market is anticipated to reach more than $2 billion by 2030, we’re highly encouraged by the opportunities that lie ahead of us.

Turning to slide nine for more on our recently announced restructuring initiative. From what you’ve heard from me already this morning, I hope the takeaway is clear. We’re incredibly focused on delivering sustainable profitability and improved margins for the company. As our near-term demand environment is softened, we’re responding with swift and decisive action to right-size our cost structure while preserving the critical investments that will drive our future growth. In order to accomplish this, we’re targeting an incremental wave of restructuring actions expected to deliver between $45 and $55 million in annualized savings by the end of 2024. The initiative will focus on optimizing our operations, an incremental headcount reduction of up to 10%, cost reduction with third-party contracts, and the rationalization of geographic locations across all facets of the company.

While these actions are never taken lightly, they’re necessary for our business and will focus on three very specific goals. The continued reduction of operating costs, improved customer quality and delivery reliability, and the essential support in R&D that will drive our future growth. Moving then to slide 10, it’s impossible for me to speak to our technology roadmap without first taking a step back. Just over 35 years ago, it was our Co-Founder and Chief Technology Officer, Chuck Hull’s curiosity and desire to improve the way products were designed and manufactured that served as the spark of innovation that ignited the 3D printing industry and 3D systems as a company. Since then, that same spark continues to fuel 3D systems innovation as the company works side by side with its customers to change the way products are manufactured and health care is delivered.

And only a few weeks ago, I had the great honor of attending a ceremony at the White House where Chuck Hull received the National Medal of Technology and Innovation, the United States’ highest honor for technological achievement, awarded personally by President Biden. Simply stated, Chuck’s impact and 3D Systems Innovation Engine aren’t slowing down. I’m exhilarated by the pipeline of technologies that we’re sharing this week at Formnext and what we have on the horizon for 2024. Over the last few years, we’ve focused intensely on acceleration of our new product introductions, changing the way in which we identified and executed these programs. While the first of these new products entered production this year, the acceleration moving forward will be dramatic.

In short, we plan to release a record number of new products between now and the end of 2024. These include a tripling in the launch of new printing platforms in 2024 versus 2023, significant system enhancements to our current fleet, a record number of new materials and applications, and several post-print accessories that are key to our customers’ need for their production environment. To highlight a few examples of our new products, we’re launching new high temperature polymer and metal materials that greatly expand the number of customer applications. These new materials bring high temperature performance to vast new levels as well as providing outstanding heat transfer and environmental resistance for applications ranging from rockets to data centers to consumer products and even shipbuilding.

As a result of our recent Wematter acquisition, which closed in early July, we’re formally introducing the SLS 300. This closed loop system is designed to operate in a smaller footprint in production environments or even outside of a manufacturing floor such as an office, material research lab, or workshop, making SLS available to a broader range of customers with a high reliability, affordable solution for production and use parts. With the SLS 300, it’s possible to accelerate product development and in-house volume production with increased flexibility, lower risk, and reduced manufacturing development costs. Just this week at Formnext, we’ll debut the latest configuration of our DMP Flex350 platform, the Flex350 triple. This compact three laser system offers a larger build capacity on the same machine footprint to produce parts with seamless surface quality.

It’s compatible with a host of materials to widen the breadth of application in industries such as aerospace, medical devices, and implants, consumer goods, petrochemicals, food, and pharmaceuticals. When our new product development pipeline is viewed in tandem with our manufacturing insourcing efforts, you can now see the culmination of our strategy to accelerate new product introduction while reducing our product costs to greatly enhance value to our customers and create value to our shareholders alike. While these are only but a glimpse of what’s to come, I hope we’ve not only demonstrated our passion to accelerate the adoption of additive manufacturing through technology innovation in the markets we serve, but also the surgical precision and execution will apply to the path of achieving sustainable profitability and significantly enhanced shareholder value ahead.

Before turning the call over to Andy Johnson, I want to publicly offer my sincere appreciation for Andy stepping into the Interim CFO role several weeks ago. Andy, you’ve done a terrific job for us, not missing a beat in any facet of your responsibilities. Thanks and very well done. So with that, I’ll turn the call over to you, Andy.

Andrew Johnson: Thanks, Jeff, and good morning, everyone. I’m now moving to slide 12. Third quarter sales of $123.8 million decreased 6% from the prior year, primarily reflecting the previously discussed and expected impact in our dental orthodontics business. As Jeff mentioned earlier, a tighter capital spending environment also led to softer than expected revenue results more broadly across the company related to printer sales. Specific to our segments, industrial solutions delivered revenues of $71.4 million, growing nearly 5% from the prior year. While printers and software grew from the prior year, it was partially offset by a decline in materials and overall performance softer than anticipated from our last call. Healthcare Solutions revenues of $52.

4 million declined 18%. As mentioned, this was primarily driven by the decline in our dental orthodontics business of 39%, relatively in line with what we had assumed coming into this year. Additionally, software printer sales throughout the remainder of healthcare solution segment also declined from the prior year, although this was somewhat offset by the technical milestone progress in our regenerative medicine business, totaling approximately $4.5 million. Lastly, as Jeff mentioned, we continue to make solid progress in the personalized healthcare solutions business with growth of approximately 7% in the third quarter. As we look forward, we continue to expect many of these broader macro demand issues tied to capital investments to persist into 2024.

And while the company has historically benefited from fourth quarter ramp in revenues, we are expecting a more modest revenue improvement in the upcoming quarter. And specific to our dental business, we are continuing to expect an annual full year decline in revenue of approximately 35%. Turning to our gross margin performance now on slide 13. Non-GAAP gross profit margin in the third quarter of 2023 was 44.8%, an improvement of approximately 490 basis points from prior year and approximately 590 basis points sequentially. As you’ll find on the chart below, a significant driver in the improved margin performance relates to technical milestones progress in regenerative medicine. This specific item contributed approximately $4.5 million of revenue recognized at 100% margin.

It is a result of a multiyear effort in our regenerative medicine program and validation of the intense focus applied by our internal team in partnership with United Therapeutics. Normalizing for this, non-GAAP gross margins for the third quarter were approximately 42.7%, a 380 basis point improvement from the second quarter of 2023, as headwinds associated with the sequential drop in volume were more than offset by continued efficiencies and cost optimization and favorable mix given lower printer sales. While Jeff touched on it, it’s important to reiterate that our operational efficiencies are starting to deliver a tangible impact evidenced in our current results. As such, we believe it’s reasonable to expect a year-over-year improvement in gross margin performance for the fourth quarter.

However, we would also expect product mix to be a sequential headwind. Additionally, regenerative medicine-related milestones are tied to specific technological progress and are not expected to have this level of impact on a regular basis. Moving to slide 14. Adjusted EBITDA was $4.7 million for the third quarter of 2023. This represents an improvement of 5.1 million from the prior year and 11.6 million from the prior quarter. Our strong adjusted EBITDA performance was primarily driven by our cost optimization and efficiency initiatives, progress in regenerative medicine, and partially offset by lower sales volume. Adjusted EBITDA also includes an approximately $2 million benefit associated with reduced incentive compensation expense. While we expect continued progress and momentum on all aspects of restructuring initiatives to have a positive impact on profitability, given the one-time benefits of the regenerative medicine and incentive compensation items discussed, we would expect adjusted EBITDA to be approaching breakeven for the fourth quarter, given the expectation of a modest sequential revenue improvement with less favorable mix.

Net loss for the quarter was $11.7 million, primarily driven by the factors noted in addition to a reduction in earn-out liability associated with a previous acquisition and impairment on intangible assets. This resulted in a diluted loss per share of $0.09 and diluted non-GAAP income per share of $0.01. Now turning to slide 15 for an update on our balance sheet. We ended the quarter with approximately $446 million of cash in short-term investments on hand. The decrease in cash throughout the first three quarters of the year was due to cash used in operations of $72 million, capital expenditures of $21 million, and acquisitions and other investments of $29 million. Looking forward, we see a sizable opportunity to drive improvement in free cash flow given our current inventory position, which has been inflated due to the foundation laid by our multiple insourcing actions over the last two years.

As the benefits of our insourcing actions will start to gain traction, we are targeting a reduction of over 20% in inventories in 2024 as an important driver for cash flow. Now finishing up on slide 16. Responding directly to the current environment, we announced an additional restructuring initiative expected to deliver $45 to $55 million in savings by the end of 2024. This effort is incremental to the approximately 7 million we executed on following our previous announcement in May. As Jeff previewed, these costs will include continued actions to augment efficiencies throughout our operations and supply chain organizations, headcount reductions across functions of up to 10% of our current employee and contractor population, an intense focus on reducing third-party costs through renegotiation and termination of certain identified contracts and run rate spend, and an intense focus on optimization of our geographic footprint.

These actions will commence this quarter and we expect a significant majority of them to be executed on by the end of the first quarter 2024. With respect to operations and supply chain efficiencies, we are very pleased with the progress achieved over the last few quarters as evidenced by our gross profit margin improvement. As we look toward 2024, we expect to begin to realize the savings of our insourcing efforts over the past two years, which coupled with newly initiated supply chain cost down projects will contribute materially to the success of our restructuring efforts. Geographic optimization continues to present a significant cost savings opportunity for us. As the world settles into a post-COVID hybrid work environment new normal, we are focused on bringing our teams together in sites where they can best collaborate and innovate within the office, the lab or the manufacturing floor.

During 2024, we plan to integrate our sites across the globe to better align our human, technological, and production resources. Our plans include a consolidation of sites by at least one-third from our current footprint. As it relates to overall headcount, our restructuring efforts will include reductions of up to 10% of employees and consultants and will spread across the entire organization. I’d like to reiterate Jeff’s earlier sentiments that these decisions are very difficult and not to be taken lightly. We expect restructuring severance cash costs to be in the range of $4 million to $6 million. In totality, our restructuring actions will improve both our cost of goods sold and our operating expenses. We currently expect approximately two-thirds of the cost take-outs to reduce OpEx and the remaining third to drive improved gross profit margins.

We look forward to updating you on our execution progress in future quarters as we further position 3D systems for near-term profitability and critical investments and innovation that will drive sustained long-term profitable growth. I’ll close by noting that while our expectations may have changed over the past few months, we’ve approached our business with a consistent philosophy throughout this year, and we believe our third quarter results, despite some one-time benefits, are a progressive step in that direction. We are adamantly focused on positioning the company to deliver sustainable profitability and to protect our mission-critical investments that drive future growth. Thank you all for joining us today. Operator, we’re now happy to open the line for questions.

Operator: Thank you. We’ll now be conducting a question-and-answer session. [Operator Instructions] Our first question today is coming from Greg Palm from Craig-Hallum Capital Group. Your line is now live.

See also 11 Best Dividend Stocks Yielding Over 6% and 10 Chamath Palihapatiya Stocks.

Q&A Session

Follow 3D Systems Corp (NYSE:DDD)

Follow 3D Systems Corp (NYSE:DDD)

Receive real-time insider trading and news alerts

Danny Eggerichs: Hey, this is Danny Eggerichs on for Greg today. Thanks for taking the questions, guys. I think just touching on profitability first here. Obviously some good progress in the quarter. Expect to approach break-even in Q4. How should we think about fiscal year ’24, maybe your confidence in being able to sustain that profitability and maybe if there’s a level that makes you more confident in being able to achieve and sustain that.

Jeffrey Graves: Yeah, thanks again, and good morning, Danny. Good to hear your voice. Well, there’s two. Number one, we’re not going to give ’24 guidance today. And quite frankly, the world’s just too volatile out there. The difficulty really is predicting top line performance. As I see it right now, as you gaze through the fog, there’s no reason that we would change our assumption on headwinds in terms of revenue performance. And we’re introducing a lot of new products, so how that adoption will be offset, or will be offsetting headwinds from the economy is yet to be determined. So we’ll talk more about that when we talk about ’24 after the next quarter. I can tell you, though, we are focused on controlling what we can control in terms of cost and that’s why we launched this restructuring initiative.

We’re moving out under the assumption that we need to get more cost out of the organization. You know we’ve targeted $45 million to $55 million and we’re moving out aggressively this quarter and as Andy ran through we’ll execute a large portion of that by end of year and then certainly by end of Q1. So we’re focused on controlling our business, running it well, getting costs down. We’ll be in a position to begin driving inventories down with our insourcing initiative kind of reaching its peak. We’ve got more to do, but we’ve done a lot of the heavy lifting already in terms of bringing materials in that you do with insourcing. So we’ve got a good availability of inventory to generate cash. We’ve got a strong focus on operating costs, which will hit both our COGS and our OpEx. So we’re looking to drive gross margin and EBITDA performance in ’24.

The top line performance will be largely dependent on just the overall economy and how it goes. You know, you’ve got economic concerns and geopolitical concerns, which right now just make it too hard to actually predict. So we’ll focus on what we can control internally, drive costs down, drive inventories down to release more cash, and with the strength of our balance sheet, we’re confident we’ll make it through that uncertain period. We’ll give you more input as we close out Q4 and look into 2024 in detail.

Danny Eggerichs: Got it. That’s helpful. And then maybe just touching on maybe this new product cycle sounds like a lot of exciting stuff coming here in the upcoming year. Maybe just in terms of what you’re releasing, is there any emphasis on targeting certain end markets applications? And then maybe how should we think about the rollout throughout the year and what kind of contribution be expecting. I guess a lot of that’s macro dependent, but just maybe your thoughts there.

Jeffrey Graves: Yeah, and I will give you some idea on the time phasing too and the potential impact on revenue performance. But I am really excited. We’re refreshing our entire product line. This was an initiative we started a year and a half to two years ago. And it takes about three years from start to finish to get new platforms in place. And we’re going through, Danny, we’re going through a refresh of our entire portfolio. So what you’ll see next year is a tripling of our printing platforms releases versus 2023. Those span our photopolymers meaning SLA and DLP. There’s a convergence in that technology, which is really exciting in terms of ramping up precision and speed to production scale for factories. So I’m really excited about SLA and DLP technologies and the convergence of those in the New Year.

The extrusion technology with pellet extrusion is really starting to get legs. And we’ve got some new products on that front that we’ll release. And of course, we have upgrades on our metal printing platforms. So it’s clearly, as I described, very broad-based. We have a host of new materials, engineering materials that are being released with those platforms for customer use and those are engineering plastics, particularly high-temperature plastics, and flame retardant, you know, low-emissions plastics, if you will, that move us more heavily into both aerospace and automotive applications, both temperature and flame resistance are extremely important there. So we’re actually pushing hard on UL certification, moving some of these materials through that have never been done before through UL certification.

So many of those hit the market throughout 2024. And then of course continued evolution of our software platforms. So it’s very broad based. It addresses virtually all of our industrial markets. We’ve got some very exciting jetting technology coming out for both small castings like the jewelry market that will hit the market in 2024. Those will phase in. Q1, Q2, Q3 will step up in terms of the product releases. They really start to peak in Q3 as we look at it right now and kind of level off in Q4 at a high level. So historically very high, triple the number in total of printing platforms that we did in ’23 and it addresses markets broadly. The customer interest in those is extremely high. The unfortunate thing right now for us and for the entire industry, I believe, is CapEx spending is down.

So I think you’ll see the emergence of a lot more customers. And then as the economy improves, those will get traction and really drive growth in ’25. So obviously time dependent on the economy, but we’ll launch, at least launch a lot of new products in ’24 that we see as really driving growth in that ’25 to ’27 timeframe. And you never know yet that hopefully the world certainly becomes more peaceful and the economy settled down a bit in ’24. You know, it’s yet to be determined. So we’re certainly not advertising broad-based declines or things of that nature. I just don’t want to be overly optimistic with so many factors in play here as we head toward the end of the year. So we’re just trying to not get out over our skis in terms of growth projections, drive costs as much as we can and be well positioned to either sustain a downturn or be there with a strong balance sheet and investment when the growth does come back.

Danny Eggerichs: Yeah, that makes total sense. Looking forward to seeing all the new stuff this year. I’ll look forward to it.

Jeffrey Graves: Thanks, Danny.

Operator: Thank you. Next question today is coming from Brian Drab from William Blair. Your line is now live.

Jeffrey Graves: Good morning, Brian.

Tyler Hutin: Hey, this is Tyler on for Brian. Hey, sorry, this is Tyler on for Brian. I appreciate you taking my questions.

Jeffrey Graves: Sure, Tyler.

Tyler Hutin: You mentioned new production printers coming up for your metal platform. Could you just elaborate on what makes 3D systems unique in metal solutions? How do you fit in within the competitive landscape? And are you more focused on building that out organically?

Jeffrey Graves: Sure. Let me comment on that. And I would say we’ve got an exciting organic growth program with significant investment as we look forward. And along those lines, we were honored and pleased to receive this contract from the US government for development of the next generation machine. So we have an intermediate-sized platform and a large platform today, our 350 and our 500. We will continue to add power to those systems with more lasers in place. But it’s not just about the number of lasers you have in the system, Tyler. It’s about thermal management of the platform and it’s about fluid flow across the powder bed to make sure you can eliminate smoke, if you will, from the powder bed to make sure you have high integrity parts.

Our focus historically has been on health care and very high end industrial automotive and other demanding industrial applications. That will remain our focus, although I have to tell you, some of the exciting new materials that are coming out are moving us rapidly into other industrial products like shipbuilding. We can do some unique things with metal printing of nickel-based, copper-based materials, copper-nickel alloys, others that are required for demanding either thermal or environmental conditions. And that’s really where we’re going to focus is on those markets that are most demanding of quality and performance. The parts we make are extremely high density. They’re obviously suitable for human application and for demanding industrial application.

That’s really where we’re going to focus. Once you’re there and you have the materials, it’s all about throughput. So, you know, some customers want single large parts, others want multiple small parts. We’re designing systems that are application specific in that range of products. Healthcare is often a large number of smaller parts for embedding in the human body. And things like ship building and aerospace can often be single run large parts that you need extremely good environmental control. I would say environmental control is probably our number one attribute right now. We can produce the highest purity, highest density parts, I believe, in the industry. And we are scaling that with our organic investment. And Tyler, on the investment front, we’ve got so much runway.

We’ve got a nice hole in both polymer and metal technology bases today. We’re driving synergies across those. So we can get where we need to be organically through internal R&D investment. And obviously we’re not oblivious to the external environment and other companies in the industry with interesting technologies. But we can get where we want to be with internal investment in both metals and polymers. And then anything on top of that is icing on the cake.

Tyler Hutin: Thanks, Jeff. Yeah, that sounds great. And just a follow-up, a pretty short question. With the restructuring, will that create any new challenges for your new product introductions? Do you see that having any impact on like fuel installations or adoption? Can you just elaborate on how you’re handling that?

Jeffrey Graves: Yeah, thanks for asking that, Tyler. I would tell you, we’ve protected certain areas of the company heavily to make sure we can drive efficiency in our back office operations. I would tell you just those efficiencies are very important so we preserve some of those, particularly around IT, things like that, cyber security, other areas that are just essential to running the business. We’ve also taken great pains to preserve the predominance of our R&D investments, because that’s critical to the new product launch. And then obviously we have a very large sales and service team. The service team is essential to not only serving our install base, which is one of the largest, if not the largest in the industry, but also the installation of new products.

So those areas of the company we’ve heavily protected. We’ve found efficiencies in other areas. And certainly by reducing our number of sites and the insourcing of manufacturing and ion supply chain operations, that gives us a really nice bump in terms of cost takeout that impacts COGS and even somewhat on OpEx. So we’re very focused, we’re very proud of our gross margin performance, quite frankly. Even if you take out the one-time benefits of regenerative medicine, we’ve stepped up from 39% and change to 42.7% in this quarter operationally. And that reflects really efficiencies in supply chains and driving some of that earlier restructuring that we did in the year, without slowing down our R&D execution, we’re really proud of that. You know, on top of that, we’re thrilled to have the technical progress on regenerative medicine that boosted gross margins even further.

But to move from 39 to 42.7, we were, operationally, we were extremely proud of in the quarter, and we see, you know, further upside as we go forward. You have to be a little careful quarter by quarter, depending on revenue fluctuations, but we see continual improvements in our gross margin capability as we move through the New Year.

Tyler Hutin: All right. Appreciate all that. I’ll pass it on.

Jeffrey Graves: Thanks, Tyler.

Operator: Thank you. Next question is coming from Jacob Stephan from Lake Street Capital. Your line is now live.

Jacob Stephan: Hey guys, thanks for taking my questions. Maybe just on the restructuring initiative, could you talk about kind of the breakdown on how you see these costs coming out of the model. I know the 45 million to 55 million range, but by Q1, does that mean 60% kind of the full value quarterly or 90%? Maybe you could help us think about that.

Andrew Johnson: Yeah, I’m happy to do that, Jacob. This is Andy. So starting with kind of how you range it in terms of actual impact in ’24, our plan is, as this last phase, this current phase, somewhere between 45 and 55 to actually be realized in ’24, that’s our goal. You’ll start to see that execution this quarter, as Jeff mentioned and I mentioned in my comments. You will see, I think your estimation of somewhere north of 50% by the end of Q1’24 is accurate. We described it as significant majority, so I think that’s right in that area. And obviously when you’re talking about headcount reductions, those different geographies can be phased differently, but we’ll start on that work this quarter. You also have OpEx benefits around prioritization and integration of geographic footprint, much of which will be actioned in the, call it the first five months of the phase.

There’s certain decisions around third-party spend that we can unilaterally decide and take benefit heading into the new year, others that require some negotiation and could be phased throughout the year. And you have a continued COGS improvement. We’ve already seen that. Our gross profit margin validates the work that was done earlier this year has started to take hold and we’ll continue to see on an annualized basis even improved results from earlier phased COGS efforts. But there is continued supply chain optimization and work on the COGS side that will happen as early as this quarter and into early next year. So when you add that up, as I mentioned, it may have been sort of buried in my comments, but you’ve got somewhere around two-thirds of that total number benefiting OpEx with the remaining third in COGS.

And definitely we believe you’ll see over 50% of that is actually coming out on the next call it quarter and a half, two quarters max. So you’ll see the benefit of that for most of ’24. And that goes back to just comments and the first question that Danny raised about profitability next year. We’re going to control what we can in the P&L and when you look at costs both on the COGS and OpEx side, those are areas we can control even in this revenue environment. So we’re not going to wait around. This isn’t a December ’24 annualized takeout exercise. Jacob, this is action now, action over the next several months. You’ll start to see real benefit, we believe, to the P&L in Q1 of ’24.

Jacob Stephan: Great. That was really helpful. Thanks. Maybe just touching on the milestone payments from United Therapeutics. Obviously, this is 100% gross margin revenue, but could you just remind us on kind of when these earn-outs or the milestone payments are set to take place?

Jeffrey Graves: Yeah, I’ll take a shot at answering that, Jacob, and then Andy can supplement it as well. So, they’re geared towards technical accomplishment, and obviously we drive to a schedule on those. But we are inventing, we’re plowing a lot of new ground in that. The human lung is the most complicated object ever printed by mankind. And I don’t say that lightly. We’re driving to levels of precision and speed that have clearly never been done before with materials that are extremely new, biological materials that are very new. So it’s impossible to predict the schedule exactly. We’ve got goals and we realize payments over time. So we’re proud that we’ve achieved some of the milestones. We’re driving hard on that schedule because we want to see United Therapeutics be able to bring that product to market as soon as possible, which will help millions of people around the world.

But it’s going by definition to be a bit lumpy over time, and we won’t be able to give you a lot of warning. I will tell you, it’s not going to be material, it’s not going to be grossly material numbers as they flow through, but as they hit, there may be a certain bump. So Andy, do you want to comment on this?

Andrew Johnson: Yeah, I’ll just build off of that slightly. Jacob, so think of it this way. We’ve got a handful, call it up to 10 milestones related to long progress. If you go back a couple of years, you would note that we reflected in our revenue and at that margin level, I had 100% obtainment and achievement of a milestone and a portion of a second milestone. But the way these are recognized is via progress. So even if a milestone isn’t even 100% achieved, once it becomes probable and it’s deemed probable at a certain threshold, you start to account for it based on the progress. So if a milestone is, for example, 60% achieved and it’s probable, you may not have the milestone paid out yet, because you’re not at 100%, but you do have recognition of the milestone.

And that’s exactly what happened in this quarter, and it’s why Jeff commented that you’re not going to see this as material to any particular quarter is spot on, because these things get recognized as progress is made. So they’re not binary where they’re just hit in one quarter and they’re gone the next, but as you deem progress, you begin to account for it. This particular quarter, we had contribution from three different milestones, huge validation of the technical progress in printing a human lung, and you’ll continue to see progress on those milestones and others over the next several years. So not material to any particular quarter from a revenue or margin standpoint, but as Jeff said, periodic, perhaps lumpy, but at the end of the day, absolute validation that we’re making progress in partnership with United Therapeutics.

Jeffrey Graves: And Jacob, one last comment, because it would not be obvious from what we’re looking at from the outside is the technological synergies that we’re finding between our biological work on human organs and even our industrial printers. The level of precision we’re now able to attain and speed of printing, we can directly transfer with minor modifications now to some of our industrial printers. And that work is just underway, but it’s really exciting because it will drive the next generation of printing technology on the industrial side as well. So we’re not just dependent on these incredible, you know, implantable organs being approved by the FDA and getting it into production, there will be spinoff benefits to our other industrial and even healthcare printing systems and materials knowledge as we go through the next few years. So we feel very blessed and very excited about this entire body of work.

Jacob Stephan: Yeah, awesome. Certainly excited to see what happens there. You know, best of luck going forward to you, guys. Thanks.

Jeffrey Graves: Thanks, Jacob.

Operator: Thank you. Next question is coming from Troy Jensen from Cantor Fitzgerald. Your line is now live.

Troy Jensen: Hey, gentlemen, thanks for taking my question and congrats on the nice margin performance here.

Jeffrey Graves: Thanks, Troy.

Troy Jensen: For you, Jeff, I just want to — you’re very welcome. I want to just drill down a little bit on healthcare accidental. You know, your European competitor had a very strong core there. They’re up 13% year-over-year. You understand there are more parts and less printers, but can you just talk about the services business from Littleton versus the printer sales. I’m assuming this is like SLS and metal printers that are weak for you, but just more color would be helpful.

Jeffrey Graves: Yeah, Troy, you put your finger on it. It was really reflects a basically a build-up of inventory in our customer base with some of the implantable devices. So that degraded our printer sales in the quarter and it really was exclusively that. So both the production of implants and the sale of printers into that space was depressed. The personalized healthcare side was up very nicely. That was up 7%. And again, it’s driven by specific applications within the orthopaedic space. So, you know, the specific 510Ks we have for different joints in the body, if you will, those kind of things. Demand’s strong, personalized healthcare, we’re very excited about it. It’s delivering consistent year-over-year growth with very strong margins.

So I’m very glad we’re in that space. What hurt us in the quarter, Troy, outside of orthodontics, the dental, was the sale of printers and in part the sale of parts into the med device space where there was a build-up of inventory and I have to say their husband in cash as well and watching their CapEx spend, again, given that they’ve got some inventory available. So I expect it to be short-term, but it was a real headwind in the core.

Andrew Johnson: And I’d also add, Troy, this is Andy, that you mentioned a competitor and their performance. If you actually do an apples-to-apples in terms of the same sort of business, we’re right in line with their low double-digits growth. Our personalized healthcare includes some other things in there, but when you look at it comparatively, we’re right in that same growth profile. The neat thing, Troy, and I know you follow this closely, that anything in that whole space is the cost of customizing implants or near custom implants for people is coming down so nicely that that marketplace has really continued to just normally expand. It’s great. It brings a better solution to patients and faster and better delivery and lower cost implants for people. So it’s opening up nice market space. I really expect that trend to continue for years to come.

Troy Jensen: All right. Love to hear that. And did I hear you guys say in the prepared remarks that your material business was weaker or down? And I’m guessing that might have to do with inventory levels at the bigger economics, but any thoughts?

Andrew Johnson: Yeah, that’s right, Troy. Yeah, that’s exactly right. That’s exactly right. It was predominantly driven by that market vertical.

Troy Jensen: Okay. All right, gentlemen, well, good luck going forward, and I’ll see you in a few hours.

Jeffrey Graves: Thanks, Troy. It’s good to hear your voice.

Operator: Thank you. We’ve reached the end of our question-and-answer session. I’d like to turn the floor back over for any further closing comments.

Jeffrey Graves: So let me just close by wishing everybody well. Thank you for calling in today and we look forward to updating you again next quarter on the year and outlook for the New Year. Thanks and have a great day.

Operator: Thank you. This does conclude today’s teleconference and webcast. You may disconnect your line at this time and have a wonderful day. We thank you for your participation today.

Follow 3D Systems Corp (NYSE:DDD)

Follow 3D Systems Corp (NYSE:DDD)

Receive real-time insider trading and news alerts